Our Products

Products We Carry

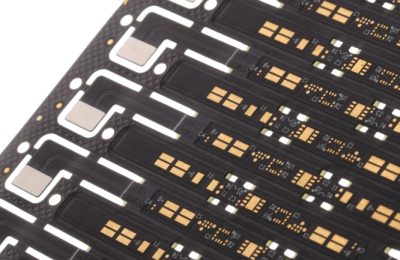

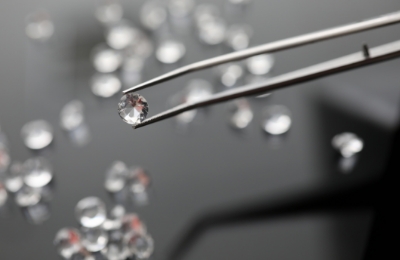

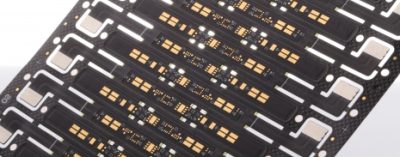

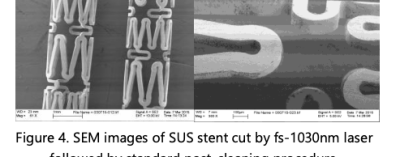

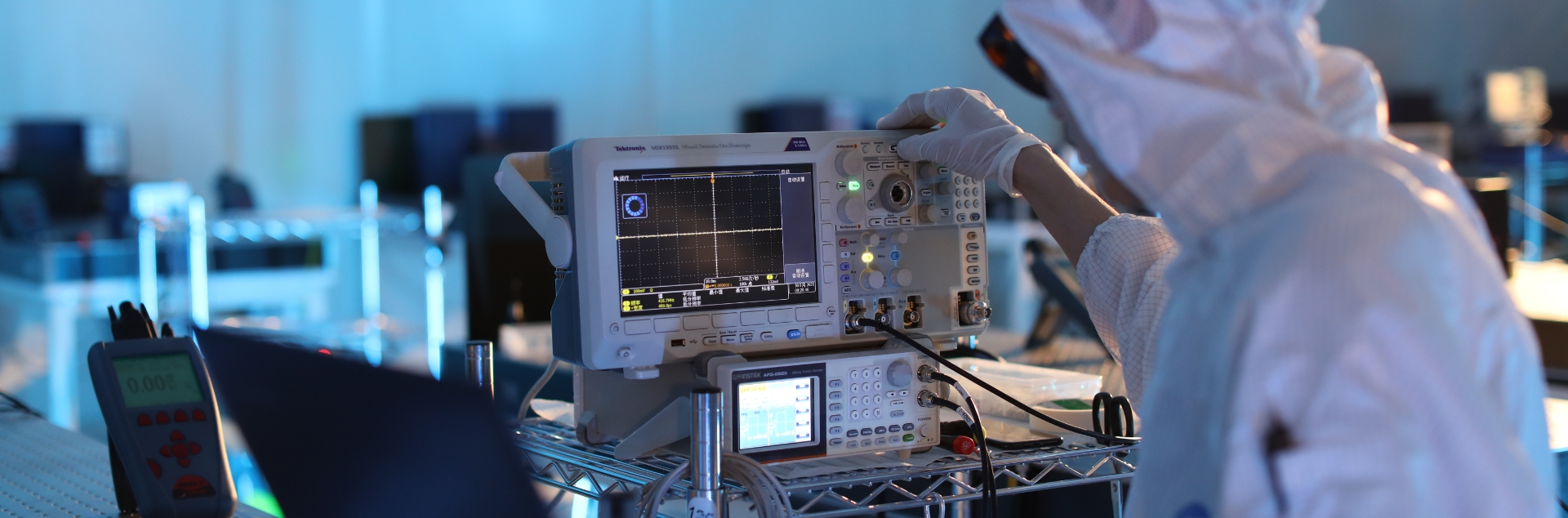

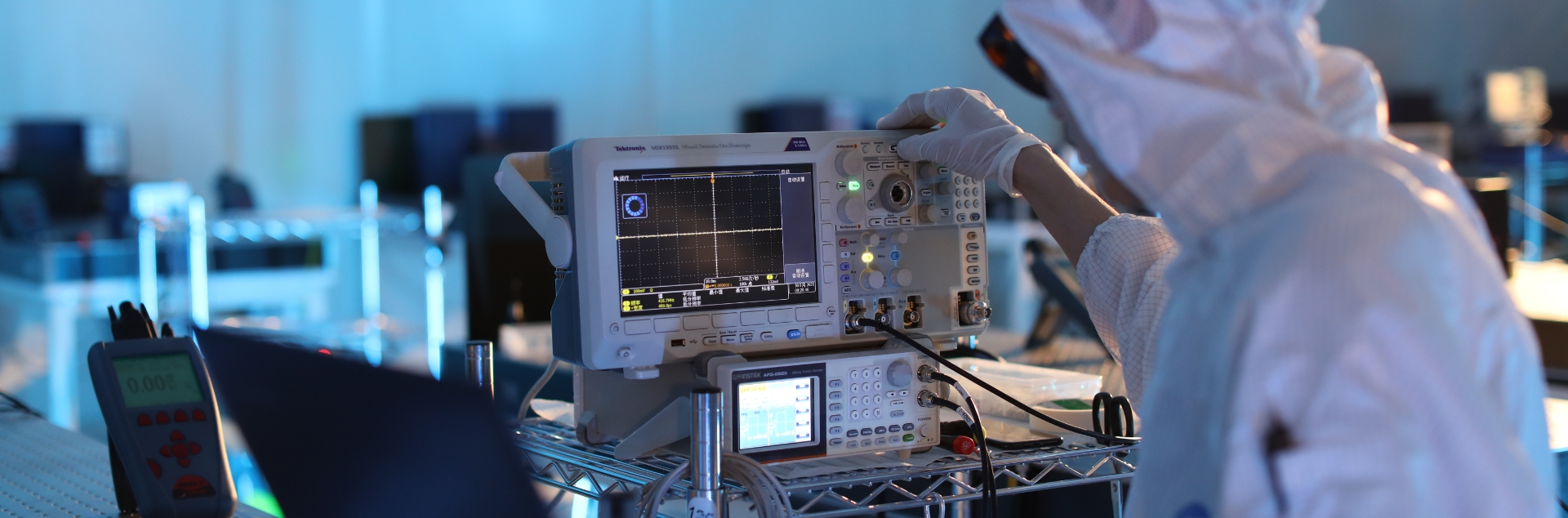

Advanced Optowave Corporation products strongly enhance our customer’s capabilities and productivity in consumer electronics, biomedical applications, semiconductor and other areas. As of today, there are more than 55,000 laser sources and laser systems installed worldwide from our innovative laser technologies. Laser for Better Life is the company mission of Advanced Optowave.

ABOUT US

Who We Are

Established in 2007, Advanced Optowave is a highly respected global supplier of diode-pumped solid-state laser solutions and laser systems. We pioneer laser technology advancements, delivering tailored solutions for various industries and research fields. Our commitment extends to providing exceptional local service and support, ensuring seamless product integration and optimal performance for our customers.

Advanced Optowave’s laser product portfolio encompasses a diverse range of pulsed lasers, including DPSS QS-ns, ultrafast, and MOPA-ns lasers, spanning wavelengths from IR to DUV and pulse widths from nanosecond to femtosecond. By leveraging innovative laser technologies and robust process development capabilities, Advanced Optowave delivers comprehensive laser application solutions to customers around the globe. With superior optical design, vision systems, motion control systems, and proprietary software, we’ve grown to be a valuable partner to Fortune 500 companies as well as small to medium sized businesses by providing cutting-edge laser solutions.

Testimonials

What Our Customers Say About Us

50,000+

laser sources installed worldwide

18 years

in business

5,000+

laser systems installed worldwide