Laser marking machines have become popular alternatives to other marking methods like dot peen markers. Their efficiency, versatility and cost savings make them an excellent fit for many manufacturers in sectors ranging from packaging to microelectronics. While you may be ready to purchase a laser marker, it’s helpful to know how to buy the right laser machine for your goals. Here are some tips for choosing the right laser marking system:

The laser’s wavelength, power and frequency will influence what type of mark you can create, so it’s important to understand how you’d like to use your laser marker. For example, an infrared beam and an ultraviolet (UV) beam will produce different marks because they are at different ends of the light spectrum.

Some of the core use cases for this technology include:

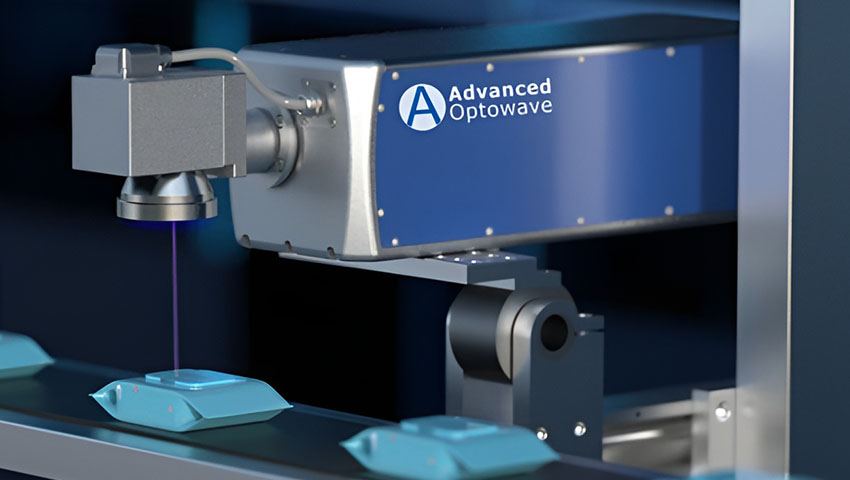

Laser marking systems come in a range of formats and designs to suit different use cases. Size is one of the core factors you’ll want to consider when selecting the right model for your operation. System size will relate to the physical size of your space and the scale of your production needs.

Tabletop models and compact workstations are smaller options for manufacturers with limited space. Portable designs can also be an excellent alternative for small operations or those that require laser marking on the field. Higher-volume systems can have footprints of various sizes. For example, Advanced Optowave Corporation has compact air-cooled lasers to fit even the smallest of spaces.

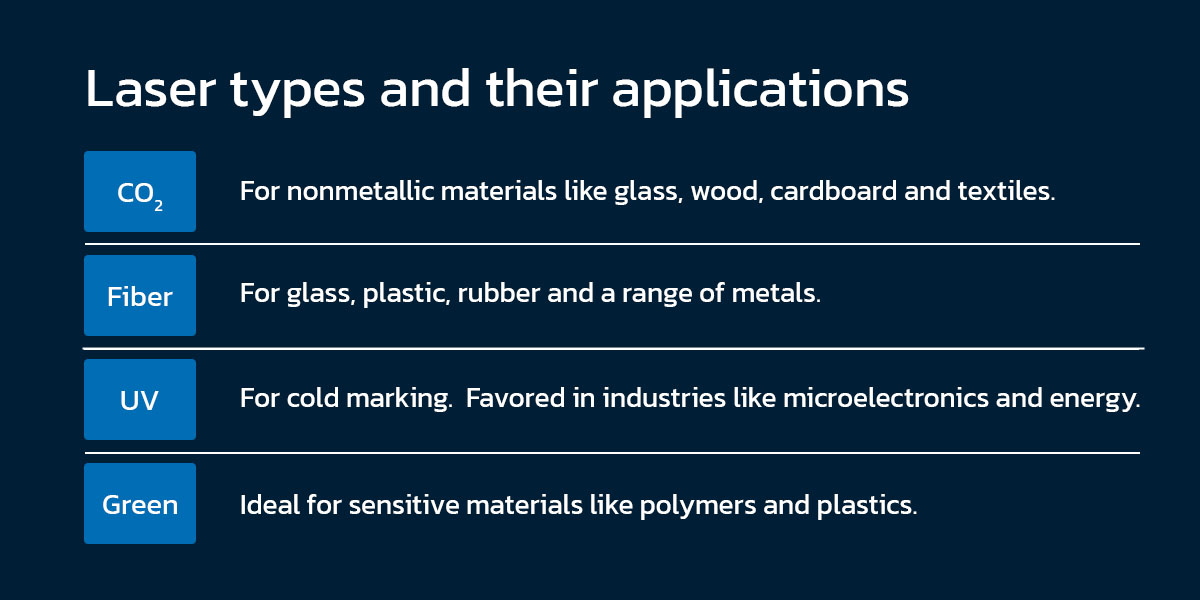

When choosing a laser marker, you should evaluate your applications and the types of materials you’ll typically work with. From there, you can decide which laser type to purchase. Laser types and their applications include:

Generally, laser marking is one of the fastest processes available for marking substrates. Among laser marking products, different technologies will offer different speeds. For example, annealing is a generally lengthier process than engraving. You’ll also want to think about how your laser system affects productivity levels on the manufacturing floor.

For instance, a tabletop model can be great for manual marking needs for small volumes of product, but it won’t support high-volume production. Ultimately, this setup will lead to downtime between each product. Mark-on-the-fly systems can be integrated into fast-moving production lines that use conveyors, robots or other forms of factory automation. This setup can lead to impressive productivity gains, as the laser marking processes are continuous and automated.

Of all the tips for choosing a laser marker, performing an in-depth cost analysis will likely have the greatest impact on your business. There are a few areas to examine when weighing the costs of a laser marking system because the initial investment will not provide a full picture of potential gains. Look into:

Laser marking systems can deliver impressive ROI for operations switching from other printing methods like dot peen markers and CIJ printers. While the initial investment is often higher for laser marking equipment, reducing consumable usage, increasing productivity and improving mark quality all contribute to gains in the long term.

System design will dictate how complex installation and operation will be. When choosing the best system for your needs, complexity in these areas should play a role. Is your operation able to accommodate the downtime for installation if you want a larger system?

You’ll also want to think about team capabilities. Laser markers operate with a computer system, but the requirements for operation will vary between products. Make sure your team includes someone capable of operating the machine or willing to learn the system to make the most of the investment. If you lack the personnel to run it, you may want to consider an automated model.

Life span and maintenance often relate to the total cost of ownership. To make your laser system worth the investment, you’ll want a product with a long life span and minimal maintenance requirements. Generally, laser markers have low maintenance requirements, especially when compared to more traditional alternatives like CIJ printers.

The life span of a laser marking machine depends on its design and how often it is used. One piece of advice for buying a laser marking machine is to source from a trusted manufacturer in the space. Speak with a manufacturer’s team to learn more about maintenance demands and projected life span.

Advanced Optowave Corporation has developed industry-leading laser marking solutions since 2007. Our experience in the industry and our commitment to research and development empower us to deliver high-performance products for critical industries like microelectronics, medical device manufacturing, automotive manufacturing and beyond. With our selection of laser marking products, you can find the right model for your applications and production scale. Get in touch with us today to learn more.