Features & Benefits

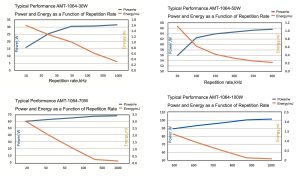

AOPico Montauk IR picosecond lasers feature excellent beam quality (M² < 1.3) with beam roundness is up to 90%. The pulse stability and power stability of the laser are excellent. The output power of the laser ranges from 30W to 100W.

The lasers can be controlled via external gate/trigger signals. Both high/low level gate and rising/falling edge trigger are available. The rising/falling edge trigger mode enables Pulse-on-demand (POD) functionality. In addition, the output power of the laser can be controlled through external analog voltage signal. The lasers also have the functions of automatic crystal indexing function, power display, laser status real-time monitoring, and intelligent diagnosis. Through the use of various internal sensors, the laser status is completely monitored, which enables remote trouble- shooting and recovery. The user experience is greatly improved as the laser is user-friendly.

With these advantages, AOPico Montauk picosecond IR lasers are the best choice for the applications of cutting various transparent brittle materials such as glass, sapphire, and full-screen displays. It not only cuts a wide range of thicknesses with good quality (virtually no dust, no burrs, debris, microcracks), but also allows for cutting of almost any shape with minimal taper (straight lines, curves, circular holes, etc.).