Manufacturers that work with hard materials may face challenges in marking applications. Traditional marking tools may experience increased wear with hard materials, or clarity may decrease over time.

Laser marking is a proven marking solution for a range of materials, including super hard metals, like steel, and other substrates like ceramic. Find trusted laser marking solutions from Advanced Optowave Corporation to improve marking techniques on your production line.

Laser marking is well-regarded among manufacturers across industries for its various benefits. The key advantages include:

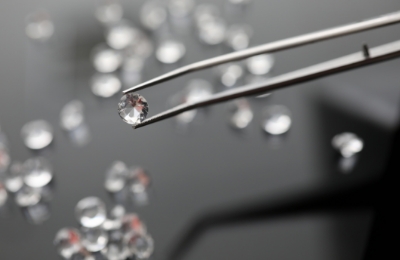

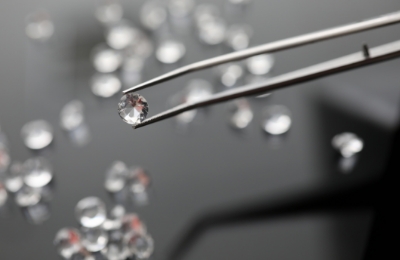

Another advantage of laser marking is its versatility. The ability to choose a laser source allows manufacturers to determine the qualities they need for their marking applications, such as the ability to work with superhard materials. Operations may use a laser for engraving diamonds or marking hard metals, like stainless steel and titanium.

Common applications for laser marking include:

Advanced Optowave Corporation manufactures diverse laser marking machines to meet various manufacturing needs. Our laser products feature a range of machine models, from workstations designed for detail work to portable models for laser marking on the field. These products also offer various laser types, including UV, fiber and CO2.

We also carry many laser sources to align with your marking goals. UV lasers offer impressive versatility for various plastics and metals, including stainless steel. We also carry IR and green lasers, including ultrafast, DPSS QS-ns and MOPA-ns lasers.

Advanced Optowave Corporation is an established leader in laser marking machine manufacturing. Our designs continue to power manufacturers across industries, and our solutions can help to improve production lines with hard materials. Contact us today to learn more.