Laser marking on glass has become an essential process for various industries that demand precision, durability, and high-quality results. As glass products continue to evolve in design and function, so too must the technology used to mark them. Among the laser technologies available, UV lasers have proven to be the most effective solution for marking glass, outperforming fiber and CO2 lasers in terms of precision, efficiency, and protection of the material. The results and comparisons presented in this article are based on the extensive findings and expertise from Advanced Optowave, highlighting the significant advantages of UV laser technology, particularly when used in combination with Advanced Optowave dynamic focusing systems for marking curved glassware.

When it comes to marking glass, it is clear that the UV laser outperforms fiber and CO2 lasers in several critical areas, including efficiency, precision, and product protection.

Explanation: Upon closer inspection, we can observe large melting points resulting from the CO2 laser and smaller, more precise material ablation patterns created by the UV laser. From a broader perspective, the surface structure produced by the UV laser appears much smoother compared to the surface created by the CO2 laser.

The reason behind this conclusion is explained by the fundamental differences between these lasers. The fiber laser, with a medium wavelength (1064nm) between the three laser types, is primarily designed for marking metals and plastics, and is ineffective on glass. Glass is a highly transparent material to infrared (IR) light, meaning that the energy from a fiber laser passes through the surface without causing significant interaction.

The CO2 laser emits IR light as well, with a wavelength of around 10,600 nm, which is readily absorbed by glass. This absorption causes heating of glass surface, leading to a process of melting on the surface. The rapid heat up of the glass surface also causes significant thermal stress. As the glass is brittle and has a poor heat conducting coefficient, this often leads to internal micro-fractures in extreme cases. The thermal effects can also result in an inconsistent marking that has different texture and depth across the entire marking area.

Meanwhile the UV laser, with a much shorter wavelength of 355 nm, reacts with the glass surface in a fundamentally different way from other laser types, allowing for high-quality marks without causing damage to the glass. Unlike CO2 or fiber lasers, which rely heavily on thermal effects, the shorter wavelength of UV laser can break molecular bonds directly without generating significant heat, which is called “cold marking” because of its minimal thermal effects. This property allows the UV laser to change the surface structure of glass in a smooth and controlled manner, causing a slight refractive index of the surface, which results in a clear, crisp mark.

Additionally, the shorter wavelength of UV lasers allows for a smaller spot size, typically around 25 µm, compared to 100µm with CO2 lasers. This smaller spot size enables highly detailed markings, which is crucial for industries that require fine logos, serial numbers, barcodes, or intricate designs.

Moreover, a key advantage of the UV laser over the CO2 laser is its significantly faster marking speed, which is due to the UV laser’s ability to directly interact with the glass surface rather than relying on thermal effects. This feature avoiding the time-consuming heat buildup and dissipation required by the CO2 laser. In a comparison test, marking the same pattern on a glass bottle, the UV laser is 63% faster than CO2 laser while delivering superior precision and quality, with minimal risk of thermal damage or surface inconsistency. This makes UV lasers particularly suited for high-volume production where speed and quality are critical.

In real glass laser marking production, the curved surface of glassware often requires the use of a rotary chuck to help maintain laser focus on the desired marking area, as traditional 2D laser marking systems keep the laser’s focal point at a fixed height. However, this method frequently results in difficult positioning when loading the products, also, users often need to change chucks to accommodate different glass sizes, adding complexity and setup time to the production process.

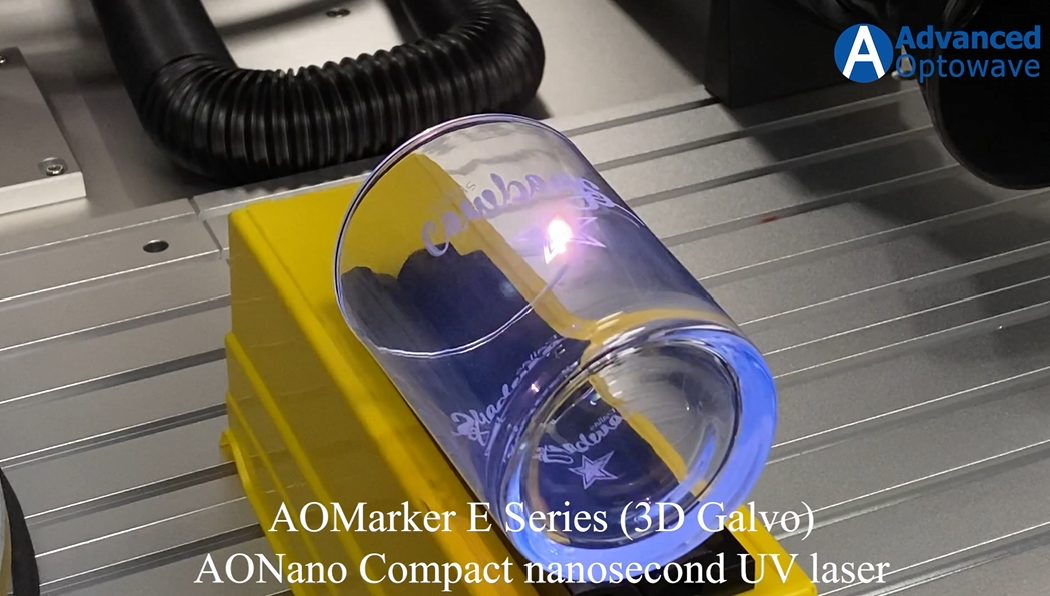

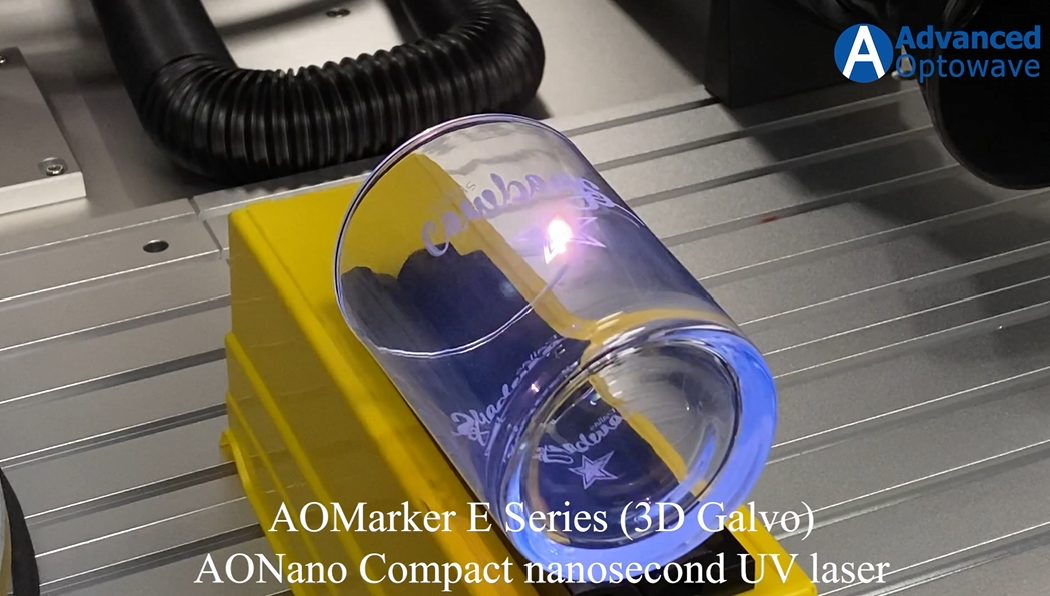

To overcome these challenges, a laser marker with Advanced Optowave’s dynamic focusing technology offers a more versatile solution. This technology eliminates the need for a rotary stage by allowing the laser’s focal point to continuously adjust and “follow” the surface of the glassware, even as the shape curves or varies in height.

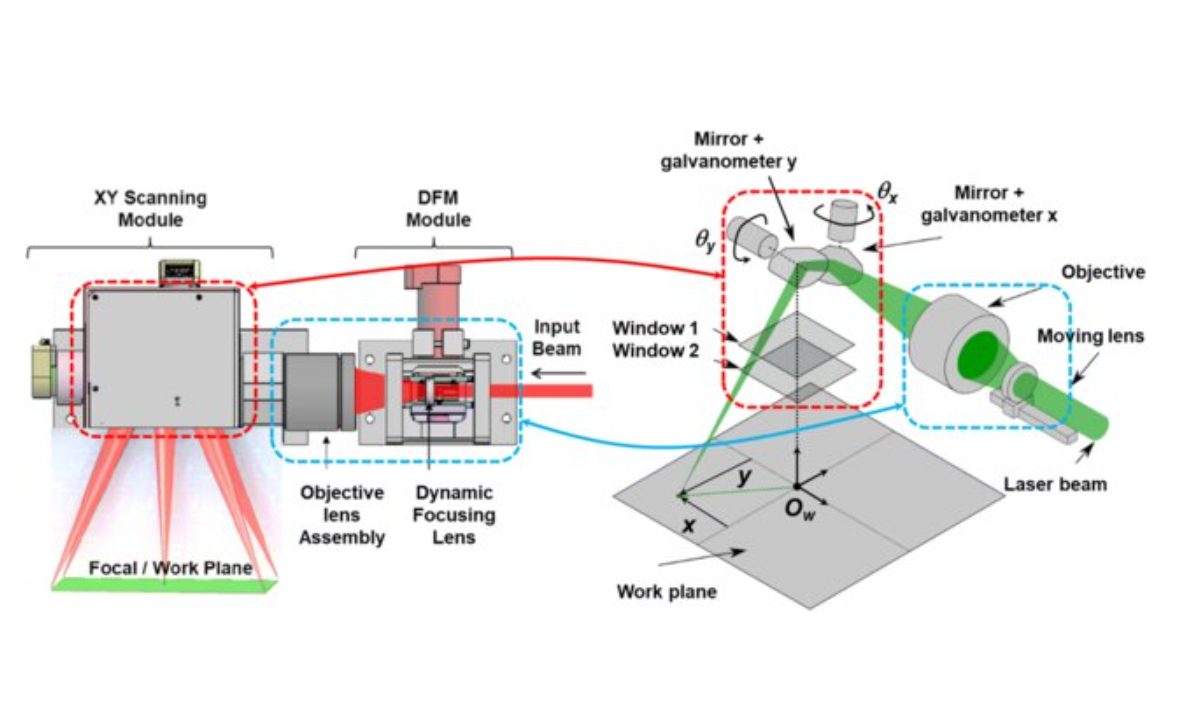

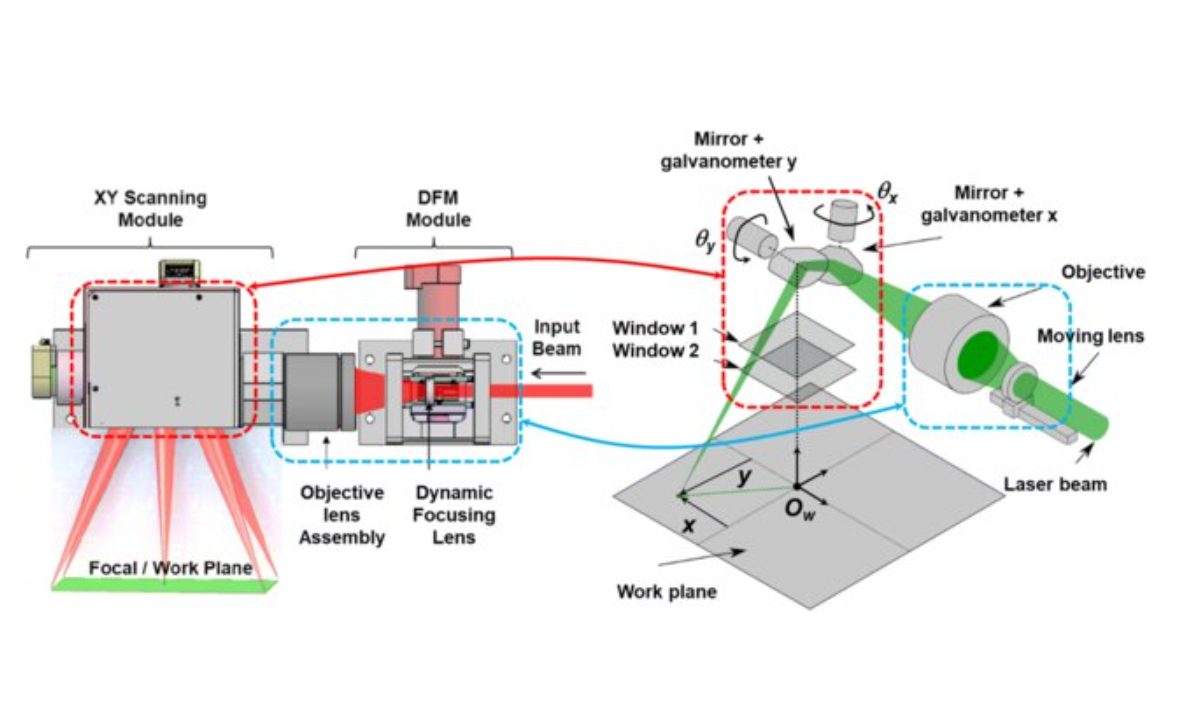

A laser system with this technology is said to be equipped with a 3D galvo-scanner. It achieves this by incorporating the Advanced Optowave’s dynamic focusing module, which uses a movable lens on the beam path to shift the focal point along the Z-axis while the X and Y axes are controlled by the general 2D galvo-scanner. The beam is constantly refocused to stay aligned with the glass surface, ensuring precise, uniform marking across the entire curved area without going out of focus. Users can input the dimensions, or even upload a 3D file of the glassware into the software, which allows the control system to calculate the necessary adjustments to keep the laser focused at the correct depth throughout the marking process. This eliminates the need for different chucks and rotary stages, making the system much more flexible and efficient, especially when dealing with various sizes and shapes of glass products. This will save a tremendous amount of set up time for the laser which will give you more time to complete jobs and increase productivity.

UV laser marking offers clear advantages over fiber and CO2 lasers when it comes to glass applications. UV lasers enable high-precision, cold marking that prevents thermal damage, allowing for clean, sharp, and detailed marks on glass surfaces. Combined with Advanced Optowave dynamic focusing technology, which eliminates the need for rotary stages and enhances the system’s adaptability, UV laser markers are the most versatile and efficient choice for marking curved and irregular glass products. This technology not only ensures superior mark quality but also simplifies the production process, making it ideal for industries requiring intricate designs, logos, and identification on glassware while meeting customer production demands.

Reference