Product lines across industries have strict production demands, and downtime causes delays that negatively affect their output — and their bottom line. With the right marking system, your operation can overcome the causes of printer downtime and meet production goals.

Printer downtime can be a significant challenge for operations, and it may stem from a range of potential causes.

While staying on top of ink quantity is a challenge of its own, improperly stored ink or expired ink can cause printer downtime as well. Poor ink quality can also cause damage to the printer, leading to additional repair costs.

Clogged printheads are a typical cause of commercial printer downtime. As an ink printer operates, dried ink and other debris can collect on the printhead, affecting overall print quality. When the printheads become too clogged, the printer can fail completely. Clogging commonly occurs from deferred maintenance, but it can also result from low-quality ink.

Factors like humidity, dust and temperature may affect printer quality and function.

Electrical power surges can disrupt the printing process and cause downtime. Static electricity can also cause problems by causing ink drops to stick to the printhead. Over time, this leads to clogged printheads and can result in damaged parts. Static electricity may disrupt other critical parts of the printer as well, including controllers and sensors.

Mechanical components of a printer may also cause downtime. Malfunctions of essential parts such as gears, rollers and belts often occur with deferred maintenance and inspection. Improperly handling a printer may cause wear and tear on mechanical parts.

Printers rely on various software and firmware downloads to function. When these fall out of date, they can cause printer issues that lead to downtime on the production line.

CIJ printers are among the most commonly used printers in commercial and industrial spaces. Despite their benefits, they’re prone to an array of issues that impact productivity.

Ink viscosity refers to the thickness of the fluid. When the viscosity is too high, the ink will stick to the ink tube, resulting in insufficient supply to the inkjet. This phenomenon often occurs in lower temperatures.

Low ink viscosity means the ink is too diluted. The looser fluid leads to a spray effect that causes ink to accumulate on the nozzle. These blockages eventually reduce print quality and require frequent stoppages for nozzle cleaning.

An extra high-tension fault (EHT) is a type of electrical failure that commonly occurs with CIJ printers. This fault may also be referred to as a high voltage fault, and it will likely stop printing completely, though you may notice reduced print quality before total failure. The source of this failure is most often a tarnished, dirty or poorly connected contact on your printer’s circuit board.

Makeup fluid is an additive for CIJ printer ink that maintains ink viscosity by preventing evaporation. Inadequate levels of makeup fluid can then cause viscosity issues, like clogged lines and poor drop quality. Makeup fluid and ink ratios need to be regularly inspected to ensure acceptable print quality.

Overall, ink and ink systems are the primary causes of product line downtime. When your product line relies on ink systems, you can expect to confront a range of failures.

For an inkjet printer to operate, the ink system must have the proper flow rate. When the flow rate is too high or too low, print quality can decrease, and clogs or blockages can stop printer operation completely. Low flow rate causes faded or inconsistent printing results, leading to product tracking issues further down the product line. A high flow rate will inundate the printhead and cause blockages. Flow rate issues are typical for CIJ printers.

Air pressure is a key factor in ink flow. Leaks in components such as supply lines and ink reservoirs result in pressure drops that lead to flow rate issues. Regular inspections and preventive maintenance may reduce occurrences of leaks, though printers with high output demands are particularly prone to this type of wear.

The meniscus is a curved surface of ink that rests on the outside of a nozzle when a printer is not fired. This curve is achieved through the ink’s surface tension and the difference in pressure between the ink and the air surrounding it. The meniscus is essential for preventing the ink from free-flowing when the printer is not being fired.

Incorrect meniscus pressure can result in ink overflow, low print quality and blockages that cause downtime. Meniscus pressure may be affected by clogs or damage in other parts of the ink system. Environmental factors, such as ambient temperature, also influence ink’s ability to create a meniscus.

Every ink system will have ink viscosity requirements to ensure optimal wetting and adhesion to your substrate. In some cases, adhesion issues may still occur with correct ink viscosity. In these cases, pretreating the substrate can improve wetting and adhesion. However, pretreatments add extra processing time to product lines.

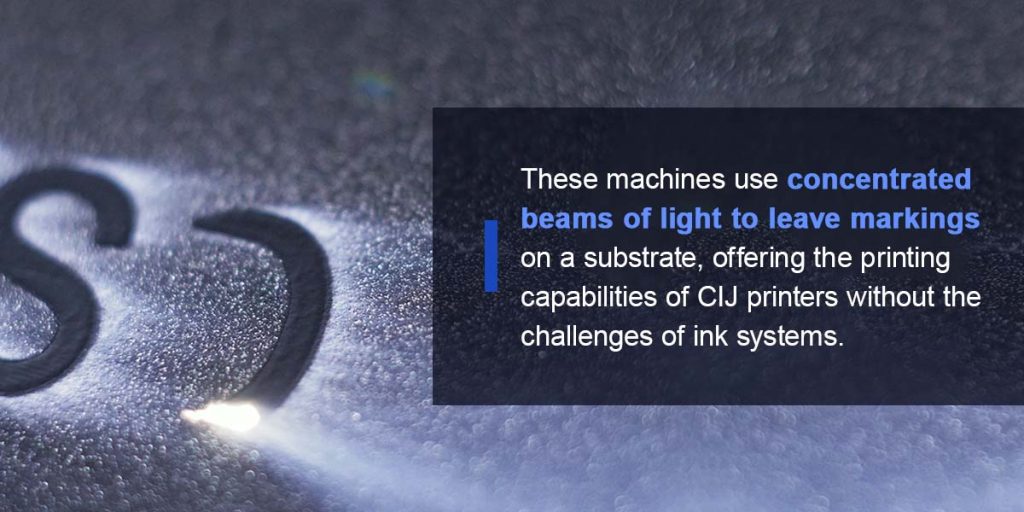

Laser marking systems are an advantageous alternative to inkjet printers. These machines use concentrated beams of light to leave markings on a substrate, offering the printing capabilities of CIJ printers without the challenges of ink systems. Particularly, marking on the fly systems deliver high-speed marking that meets high-volume production needs for manufacturers.

Among marking on the fly systems, operations can choose from three categories based on application demand:

Laser marking systems have lower operational costs than CIJ printers and are considerably more versatile in their substrate compatibility. These systems also offer impressive speeds, making them ideal for high-volume product lines. The non-contact, inkless process eliminates many of the challenges of traditional CIJ printers, including ink levels, clogging and adhesion challenges.

View Laser Marking on the Fly Products

Advanced Optowave Corporation is a laser solution provider that delivers innovative laser marking technologies for operations across industries. Contact our team today to upgrade your CIJ printer to a laser marking system.