Laser engraving technology has become a critical part of manufacturing. Laser engraving creates permanent designs on metals, plastic, organic materials and more. While laser engraving provides lasting results, materials need additional support post-marking to ensure durability and design quality.

Painting after laser engraving is a critical step in the production process. Paint is required to maintain the mark’s integrity while achieving the desired finish. The interaction between the laser engraving and paint enhances the design’s look for better results. Understanding the post-engraving process and painting materials will help elevate the engraving process.

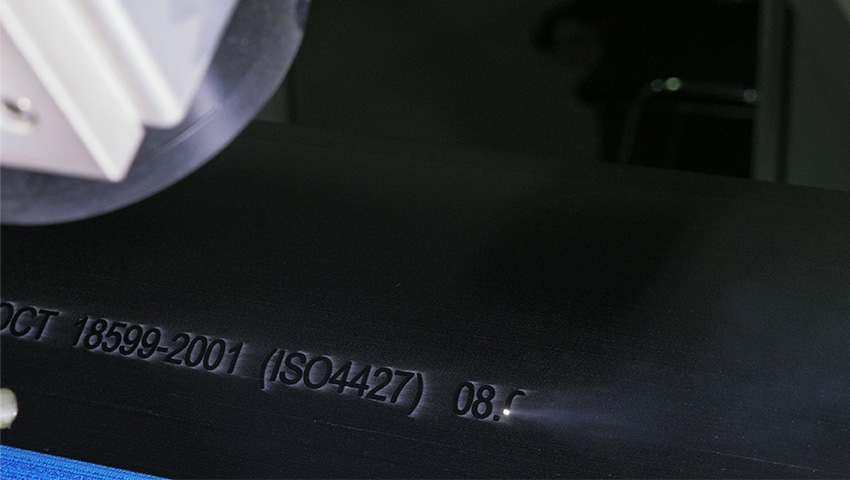

Laser engraving is a high-precision technique that creates detailed designs. The process uses a high-powered laser beam on the surface of the material. The engraving machine controls the laser’s focus and intensity, influencing depth and precision. As the machine moves the laser across the material, it removes layers and leaves a permanent mark. The engraving can be left as-is for a raw-looking finish or apply paint or coatings to enhance it further.

Unlike laser marking, which leaves a mark, laser engraving vaporizes part of the material to create the result. Since the engravings are made from the material, they are highly durable and detailed. Each material reacts differently with the laser, affecting engraving depth, color contrast and texture.

Yes, you can laser engrave on paint. However, it is essential to understand the difference in results. Laser engraving on paint involves removing the top layer of paint from some of the material. This technique is common when creating visible markings on coated materials.

Engraving on paint is not always the best approach. You must consider long-term durability and appearance. Over time, the engraved paint’s exposed edges can become vulnerable to wear, and you may see chipping and peeling near the engraved sections. This wear can diminish the product’s look and overall life span.

Painting over laser-engraved surfaces offers you more control over the final appearance, improving consistency. Additionally, you can protect the engraved areas with paint for better durability. Deciding when to paint comes down to personal preference, but painting second can deliver better long-term results.

Painting after laser engraving can improve your materials’ durability and aesthetics. When you engrave and apply paint, you create a seamless coating over the engraving and the material. This coating protects the engraved area from external elements and makes the substrate look cohesive. This protection is critical in industrial environments where materials are exposed to harsh conditions, as these conditions quickly wear away unprotected engravings.

Additionally, painting after engraving allows you more freedom during the design stage. Applying the paint or coating after engraving lets you apply contrasting colors or finishes on the substrate. You will improve readability and make markings stand out. Post-engraving painting also lets manufacturers apply specialized coatings. Consider using coatings that resist corrosion, ultraviolet (UV) rays or chemical exposure. As a result, you can enhance product integrity to handle demanding industrial applications.

While you can paint after laser engraving, the paint must work with your material and its application. Before applying any paint or coating, it is essential to test it on a small area of the material to ensure compatibility with both the substrate and the engraving.

Consider paint type if you want to ensure longevity, protection and appearance for substrates. Understanding different paint for laser-engraved surfaces maximizes your results:

Acrylic paints are popular due to their fast-drying properties. They are water-based and provide excellent substrate adhesion. You can use acrylic paint on wood, metals and some plastics. Acrylics are also available in a wide range of colors and finishes, from matte to high-gloss, improving design customization options.

When applying acrylic paint to engravings, always ensure the surface is clean. Any debris in the engraving will interfere with paint adhesion. Use multiple thin paint layers to avoid pooling — thicker layers can obscure engraving details.

Wood should be primed before acrylic paint is applied. Metals can also benefit from a primer, but it is not always necessary. After painting, allow the surface to cure completely before processing further.

Epoxy paints provide excellent adhesion and durability. They work effectively on a range of substrates but excel on metals and plastics. Epoxy is resistant to moisture, chemicals and abrasion. Choose epoxy paints for materials exposed to harsh environments.

Always use epoxy paints in controlled environments, as dust and contaminants can affect the finish. Use primers designed for epoxy paint to improve adhesion. When painting engraved sections, apply the paint evenly with a silicone brush in small circles to prevent bubbling. Even coats prevent overfilling and improve marking clarity. Cure the epoxy paint according to the paint’s instructions to ensure the best results.

Powder coating is a versatile alternative to standard paints. Apply powder coatings to the engraved sections and then cure them under heat. This process creates a solid, durable finish.

After curing, powder coatings are highly resistant to corrosion, wear and changing environmental conditions. If your products require long-lasting coatings, powder coating may be an effective solution. These coatings are available in a wide range of colors and textures, providing design flexibility.

Pre-treat engraved areas before using powder coatings. Oils, dust and other contaminants can interfere with the powder coating process. Cover the areas with powder coating and use a hard card or similar tool to scrape off any coating not inside the engraved areas. Then, cure the material.

Specialized coatings provide additional features that improve the paint’s durability. Two common specialized coatings include temperature and UV resistance. These coatings ensure your paint job can withstand the conditions the substrate will see:

While laser engraving provides clear designs, laser marking optimizes your labeling process, delivering high-quality markings before or after painting. Advanced Optowave Corporation specializes in cutting-edge laser markers that precisely mark a range of substrates.

Our AOMarker H Series Portable Handheld Laser Marker allows you to deliver accurate markings on the go. The better your marking quality, the better your end results.

With over 55,000 laser systems installed worldwide, you can trust Advanced Optowave Corporation to deliver the innovative solutions you need. Contact us today to discover how we can elevate your marking capabilities.