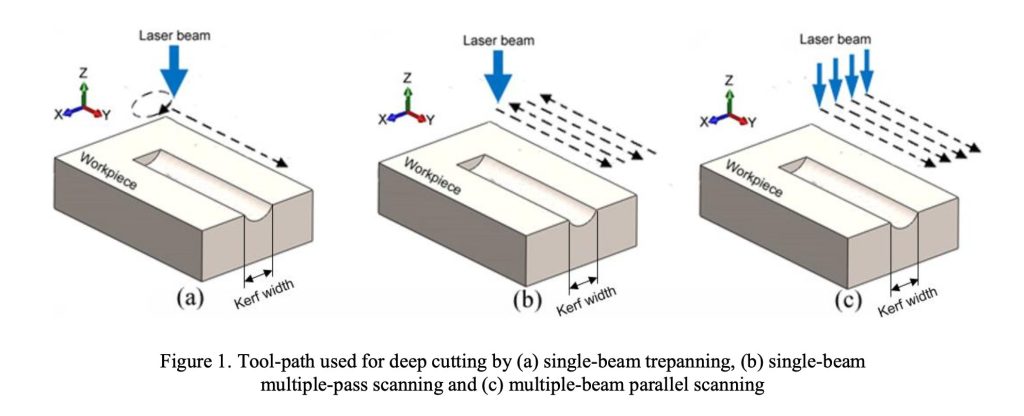

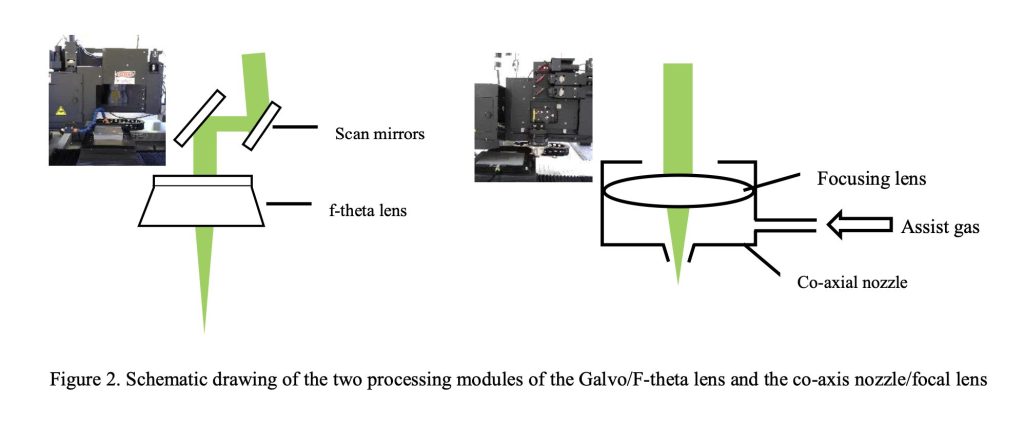

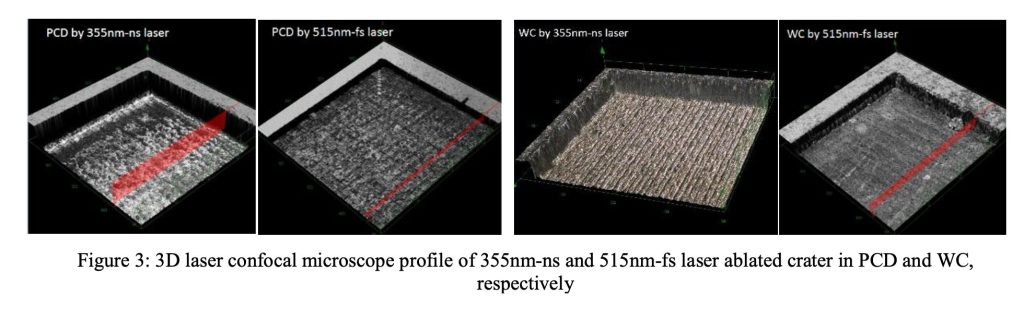

In this paper, micro-processing of three kinds of super-hard materials of poly-crystal diamond (PCD)/tungsten-carbide (WC), CVD-diamond and cubic boron nitride (CNB) has been systematically studied using nanosecond laser (532nm and 355nm), and ultrafast laser (532nm and 515nm). Our purpose is to investigate a full laser micro-cutting solution to achieve a ready-to-use cutting tool insert (CTI). The results show a clean cut with little burns and recasting at edge. The cutting speed of ~2-10mm/min depending on thickness was obtained. The laser ablation process was also studied by varying laser parameters (wavelength, pulse width, pulse energy, repetition rate) and tool path to improve cutting speed. Also, studies on material removal efficiency (MRE) of PCD/WC with 355nm-ns and 515nm-fs laser as a function of laser fluence show that 355nm-ns laser is able to achieve higher MRE for PCD and WC. Thus, ultrafast laser is not necessarily used for superhard material cutting. Instead, post-polishing with ultrafast laser can be used to clean cutting surface and improve smoothness.