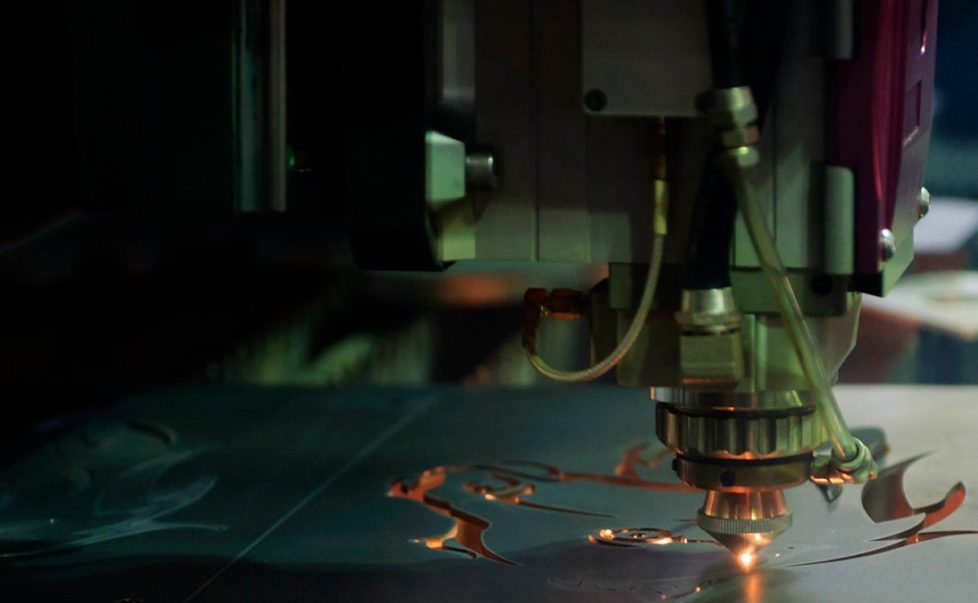

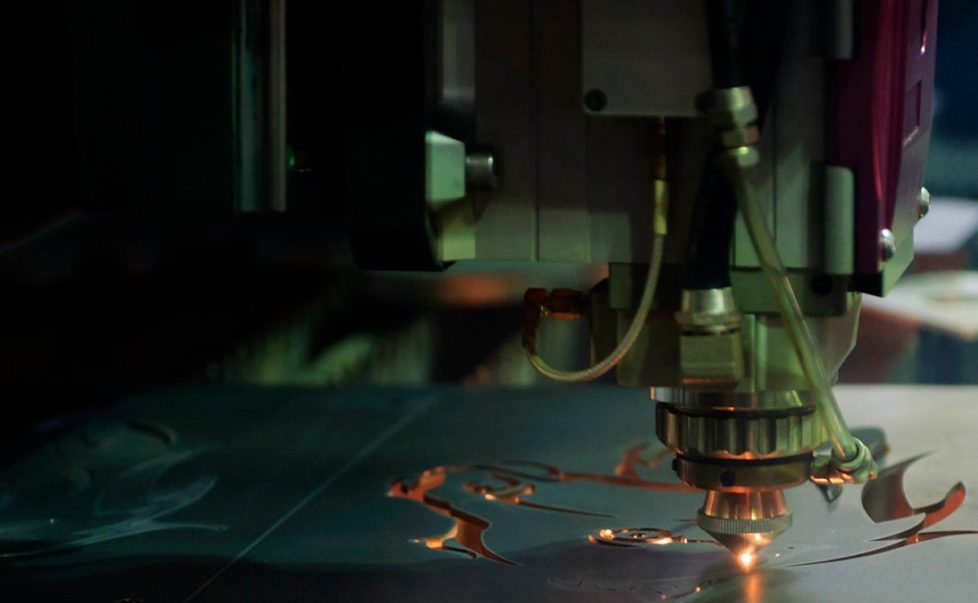

Laser technology offers several advantages over traditional methods, such as precision, speed, versatility, and minimal heat-affected zones. Common laser processing of metal includes: cutting, welding, drilling, engraving, marking, etc.

Cutting, drilling and scribing are the first applications for lasers and it continues to be one of the largest applications for lasers today. Laser cutting provides a non-contact machining method that produces high-quality, high-precision features, and in some cases, with little or no post processing which also translates into a relatively stress-free cutting process. By eliminating or minimizing the post process now, your parts can come directly from the laser tool saving manufacturing time and money.